E.DLM Loading Equipment

Application:

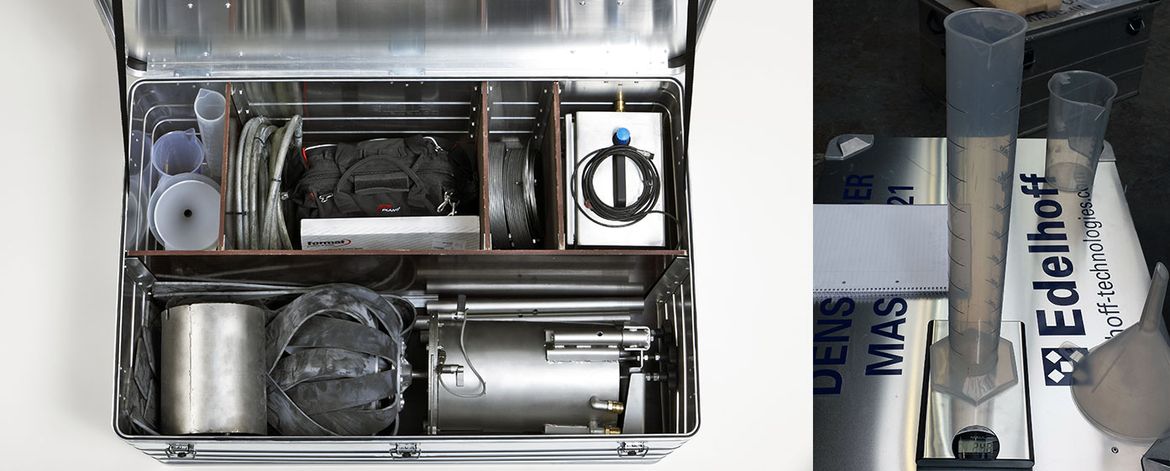

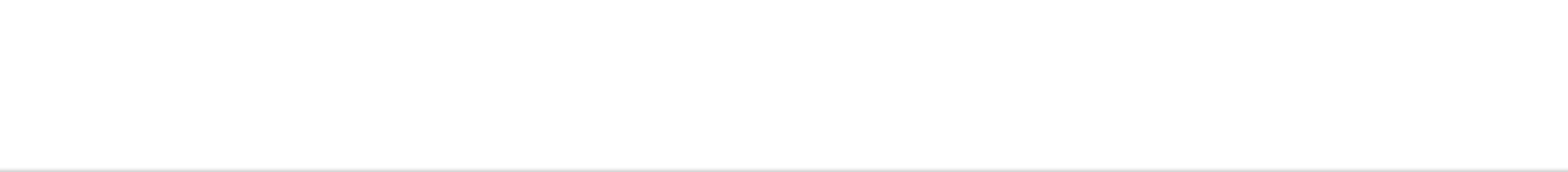

For loadings of granules / catalysts, storage tanks with a volume of up to 2 m³ are used. Edelhoff supplies 2 different types of storage containers, a standard stainless-steel container with an inlet and an outlet with shut-off devices and coupling systems for use with Dense Loading or alternatively with Sock Loading. Alternatively, a Edelhoff Dedusting Hopper is used as a storage container. This storage tank ensures a dust and break free inflow into the tank or the Dense Loading Machine. Our Dedusting Hopper is also made of stainless steel and is equipped with appropriate sieve inserts according to customer specifications.

Description:

Both storage tank systems ensure a continuous flow of the catalyst / filling material

Benefit & Advantage:

In Dense Loading it is crucial that the loading flow is never interrupted. Thus, the Edelhoff Dense Loading machine must be continuously fed with material. In Sock Loading the loading uniformity is also increased, whereas no higher density is avchieved.