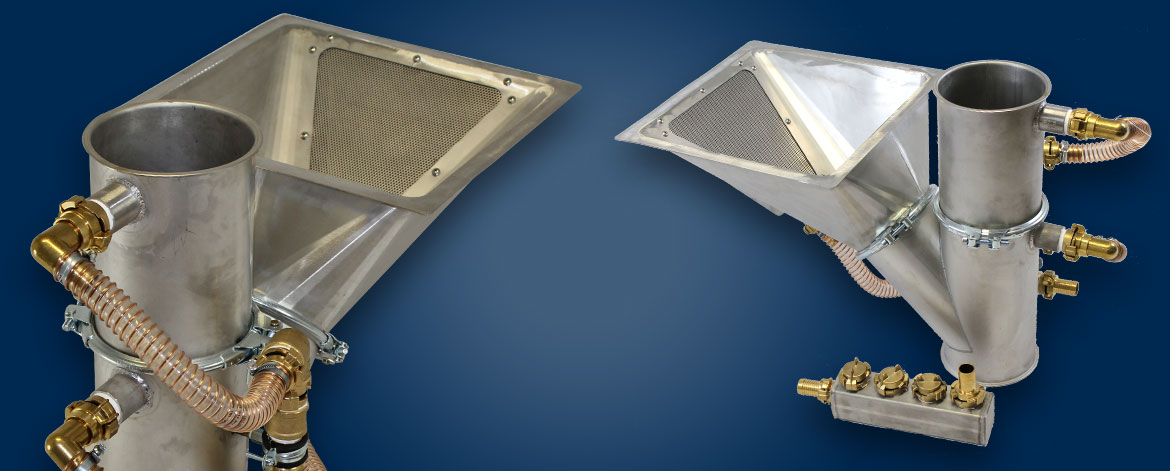

MULTIDENSETM Equipment

Application:

MULTIDENSETM is a specially developed technology for the loading of steam reformer, synthesis gas plants, ammonia plants etc. It is a further development of the Unidense technology. In this charging method, a uniform distribution of the catalyst in the reformer tube is produced while avoiding destruction of the material. During the loading process, smaller fractions, abrasion and dust are removed by multiple suction to prevent differential pressure variations. Hot spots due to density deviations within a tube are almost impossible with MULTIDENSETM.

Description:

The Edelhoff MULTIDENSETM process ensures even loading of the catalyst into the reformer tube. A uniform loading of all tubes of a reformer furnace is ensured by calculating the amount of catalyst at optimum density. Thanks to the modular construction of the Multidense equipment, the loading process is possible even in confined spaces. Re-aspiration and corrections are usually not required.

Benefit & Advantage:

The use of MULTIDENSETM makes a uniform loading of reformer tubes with catalyst in confined spaces possible. The exact filling leads to time savings and thus also to cost reduction.